Pressure seal valves are a critical component in many industrial applications where high pressure and temperature conditions are present. These valves are designed to provide a tight seal against the flow of fluids, ensuring optimal efficiency and safety. However, with so many options available in the market, it can be challenging to choose the right pressure seal valve for your specific needs. Here are some key factors to consider when making your selection.

1. Pressure and temperature rating: The first and foremost factor to consider is the pressure and temperature rating of the valve. It is essential to choose a valve that can withstand the maximum pressure and temperature conditions in your application without compromising its integrity. If you're looking to buy a pressure seal valve then you may visit QRC Valves.

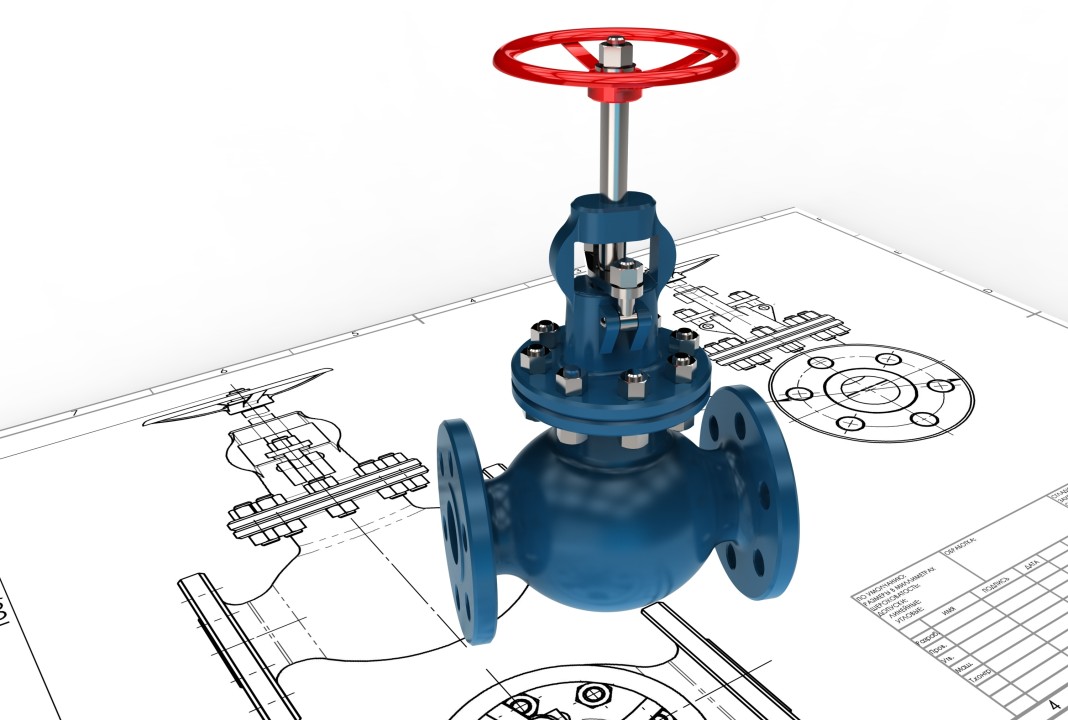

Image Source: Google

2. Valve material: The material used in the construction of the valve is crucial for its performance and durability. Different materials have varying resistance to corrosion and erosion, so it is essential to select a valve made from a material that can withstand the specific fluids and operating conditions in your application.

3. Valve design: The design of the pressure seal valve can greatly impact its efficiency and ease of operation. Look for valves with a compact and streamlined design that minimizes pressure drops and enhances flow efficiency. Additionally, valves with user-friendly features such as easy maintenance and quick installation should be preferred.

4. Compliance with industry standards: Ensure that the pressure seal valve you choose complies with relevant industry standards and regulations. Valves that have undergone rigorous testing and certification provide better reliability and performance assurance.